Hammel

Rockster

Stokkermill

VTN

Need equipment for your demolition and recovery projects?

Contact us for more details!

Stokkermill Wire Shredder | Turboflex

Description :

Cable granulator TURBOFLEX are equipped with a cell refiner downstream of the blade crusher and are available in 2 models with flow rates ranging from 170 to 350 kg/h. The presence of the turbocellular refiner allows the processing of small diameter cables (also telephone cables and data or capillary cables) without the need to modify the sorting grid or carry out costly manual work to separate the material to be processed.

Cable granulator Turboflex can be equipped with a Zig-Zag system for separating the rigid cable. Particularly robust and reliable, they enable the processing of copper and aluminium cables and copper-aluminium radiators thanks to the robust 3-blade rotating shredders. All shredders installed in the TURBOFLEX series granulators are made of a single block of steel without welded parts. The generously dimensioned motors overcome unexpected stresses, guaranteeing uniform operation and extremely low energy consumption.

Cable granulator TURBOFLEX do not require forced cooling systems due to the generous dimensioning of all process components, transport pipes and material dosing cyclones.

Cable granulator TURBOFLEX can be connected to the PS or CRS series pre-crushing machines by means of an NST series conveyor to form a complete recycling plant.

Advantages :

- Possibility to process small diameter cables without the need for costly sorting of the material to be processed (extremely fine cables, standard and large diameter cables can be processed together)

- Ease of use

- Adaptability and robustness

- Quiet operation thanks to the Silent Technology system

- Reduced maintenance time

- Low operating costs

- Do not require forced water cooling

Need equipment for your demolition and recovery projects?

Contact us for more details!

Model

Version

Engine

Weight

Need equipment for your demolition and recovery projects?

Contact us for more details!

Stokkermill Wire Shredder | Turboflex

Description :

Cable granulator TURBOFLEX are equipped with a cell refiner downstream of the blade crusher and are available in 2 models with flow rates ranging from 170 to 350 kg/h. The presence of the turbocellular refiner allows the processing of small diameter cables (also telephone cables and data or capillary cables) without the need to modify the sorting grid or carry out costly manual work to separate the material to be processed.

Cable granulator Turboflex can be equipped with a Zig-Zag system for separating the rigid cable. Particularly robust and reliable, they enable the processing of copper and aluminium cables and copper-aluminium radiators thanks to the robust 3-blade rotating shredders. All shredders installed in the TURBOFLEX series granulators are made of a single block of steel without welded parts. The generously dimensioned motors overcome unexpected stresses, guaranteeing uniform operation and extremely low energy consumption.

Cable granulator TURBOFLEX do not require forced cooling systems due to the generous dimensioning of all process components, transport pipes and material dosing cyclones.

Cable granulator TURBOFLEX can be connected to the PS or CRS series pre-crushing machines by means of an NST series conveyor to form a complete recycling plant.

Advantages :

- Possibility to process small diameter cables without the need for costly sorting of the material to be processed (extremely fine cables, standard and large diameter cables can be processed together)

- Ease of use

- Adaptability and robustness

- Quiet operation thanks to the Silent Technology system

- Reduced maintenance time

- Low operating costs

- Do not require forced water cooling

Need equipment for your demolition and recovery projects?

Contact us for more details!

Need equipment for your demolition and recovery projects?

Contact us for more details!

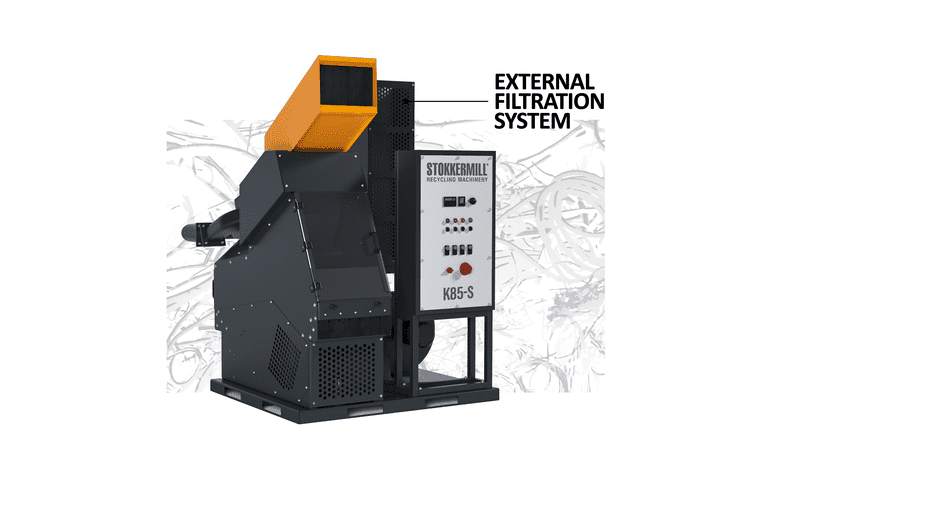

Stokkermill Copper Recycling Line | K

Description: Cable granulator with external filtration system : Cable granulator are the newest entry-level shredders in our series, On the other hand, we designed the KS series keeping the same quality as other Stokkermill cable shredders. We kept the same size of densimetric separation table and blade length. Usually, a small cable granulator has a small separation table, therefore, it is very important that Stokkermill KS series small granulators have a generous size of densimetric separation table and blade length. This is very important to get the copper that deserves quality! Thanks to the high-quality components, the K-85S and K-130S show impressive performance! We use Siemens electric motors and SKF bearings and Schneider components for the control panel. Of course, we kept the same air flow adjustment dial and reverse crusher system on the control panel. Stokkermill KS series cable and wire granulator also comes with an external filtration system with a capacity of 25 m3, therefore, it is incredibly efficient to operate without stopping to clean the machine every hour.

The possibility of increasing production capacity : The production capacity of K-85S is 80-100kg/h, K-130S is 100-130kg/h depending on input material. In addition, according to customer needs, both granulators are designed and adaptable for installing a turbo unit to process even thin cables/VHU/IT and increase the production capacity. It can be added a PS series pre-crusher and a NST series conveyor belt with a magnetic pulley.

Advantages : The new entry-level compact wire granulator for copper and aluminum cables with external filtration system, High purity output materials, High quality components: Siemens motors, SKF bearings, Schneider components for the control panel, Recover copper and aluminum powder directly from the densimetric separation table, Affordable price and minimal maintenance / 24 months warranty

Need equipment for your demolition and recovery projects?

Contact us for more details!

Model

Version

Engine

Weight

Need equipment for your demolition and recovery projects?

Contact us for more details!

Stokkermill Copper Recycling Line | K

Description: Cable granulator with external filtration system : Cable granulator are the newest entry-level shredders in our series, On the other hand, we designed the KS series keeping the same quality as other Stokkermill cable shredders. We kept the same size of densimetric separation table and blade length. Usually, a small cable granulator has a small separation table, therefore, it is very important that Stokkermill KS series small granulators have a generous size of densimetric separation table and blade length. This is very important to get the copper that deserves quality! Thanks to the high-quality components, the K-85S and K-130S show impressive performance! We use Siemens electric motors and SKF bearings and Schneider components for the control panel. Of course, we kept the same air flow adjustment dial and reverse crusher system on the control panel. Stokkermill KS series cable and wire granulator also comes with an external filtration system with a capacity of 25 m3, therefore, it is incredibly efficient to operate without stopping to clean the machine every hour.

The possibility of increasing production capacity : The production capacity of K-85S is 80-100kg/h, K-130S is 100-130kg/h depending on input material. In addition, according to customer needs, both granulators are designed and adaptable for installing a turbo unit to process even thin cables/VHU/IT and increase the production capacity. It can be added a PS series pre-crusher and a NST series conveyor belt with a magnetic pulley.

Advantages : The new entry-level compact wire granulator for copper and aluminum cables with external filtration system, High purity output materials, High quality components: Siemens motors, SKF bearings, Schneider components for the control panel, Recover copper and aluminum powder directly from the densimetric separation table, Affordable price and minimal maintenance / 24 months warranty

Need equipment for your demolition and recovery projects?

Contact us for more details!

Need equipment for your demolition and recovery projects?

Contact us for more details!

Stokkermill Wire Recycling Plant | Multiflex

Description :

Copper cable granulator of the Multi-Flex Turbo Zig-Zag series are composed of 3 units: Grinder, Refining turbine, Densimetric table.

Copper cable granulator separate significantly increases the performance and flexibility of the granulator and reduces vibration phenomena by improving the dissipation of heat produced by grinding, as well as facilitating routine maintenance.

All Multi-flex Turbo Zig-Zag systems use a TURBO cell refiner and are available in 4 models with production starting from 400 kgh.

The presence of the TURBO cell refiner allows the processing of small diameter cables (telephone and data cables or capillary cables) without the need to modify the processing grid or carry out costly operations to separate the material to be processed.

Crushers, Cable Granulator Multi-flex Turbo are equipped with a zigzag system for separating the rigid cable.

Particularly robust and reliable, they allow the processing of copper and aluminium cables and copper-aluminium radiators thanks to the robustness of the crushers.

The generously sized motors allow to overcome unexpected stresses, guaranteeing uniformity of operation and low energy consumption.

Copper Cable Granulation System Multi-flex Turbo Zig-Zag do not require forced cooling systems due to the generous dimensioning of all process components, transport lines and material dosing cyclones.

Multi-flex Turbo Zig-Zag cable granulation shredders can be connected to PS or CSR series pre-shredders by means of an NST series conveyor to form a complete recycling plant.

Advantages :

- Possibility to process small diameter cables without costly sorting of the material to be processed (extremely fine cables, standard and large diameter cables can be processed together)

- Ease of use

- Reliability and robustness

- Quiet operation thanks to the Silent Technology system

- Reduced maintenance time

- Low operating costs

- Do not require forced cooling

Need equipment for your demolition and recovery projects?

Contact us for more details!

Model

Version

Engine

Weight

Need equipment for your demolition and recovery projects?

Contact us for more details!

Stokkermill Wire Recycling Plant | Multiflex

Description :

Copper cable granulator of the Multi-Flex Turbo Zig-Zag series are composed of 3 units: Grinder, Refining turbine, Densimetric table.

Copper cable granulator separate significantly increases the performance and flexibility of the granulator and reduces vibration phenomena by improving the dissipation of heat produced by grinding, as well as facilitating routine maintenance.

All Multi-flex Turbo Zig-Zag systems use a TURBO cell refiner and are available in 4 models with production starting from 400 kgh.

The presence of the TURBO cell refiner allows the processing of small diameter cables (telephone and data cables or capillary cables) without the need to modify the processing grid or carry out costly operations to separate the material to be processed.

Crushers, Cable Granulator Multi-flex Turbo are equipped with a zigzag system for separating the rigid cable.

Particularly robust and reliable, they allow the processing of copper and aluminium cables and copper-aluminium radiators thanks to the robustness of the crushers.

The generously sized motors allow to overcome unexpected stresses, guaranteeing uniformity of operation and low energy consumption.

Copper Cable Granulation System Multi-flex Turbo Zig-Zag do not require forced cooling systems due to the generous dimensioning of all process components, transport lines and material dosing cyclones.

Multi-flex Turbo Zig-Zag cable granulation shredders can be connected to PS or CSR series pre-shredders by means of an NST series conveyor to form a complete recycling plant.

Advantages :

- Possibility to process small diameter cables without costly sorting of the material to be processed (extremely fine cables, standard and large diameter cables can be processed together)

- Ease of use

- Reliability and robustness

- Quiet operation thanks to the Silent Technology system

- Reduced maintenance time

- Low operating costs

- Do not require forced cooling

Need equipment for your demolition and recovery projects?

Contact us for more details!

Need equipment for your demolition and recovery projects?

Contact us for more details!

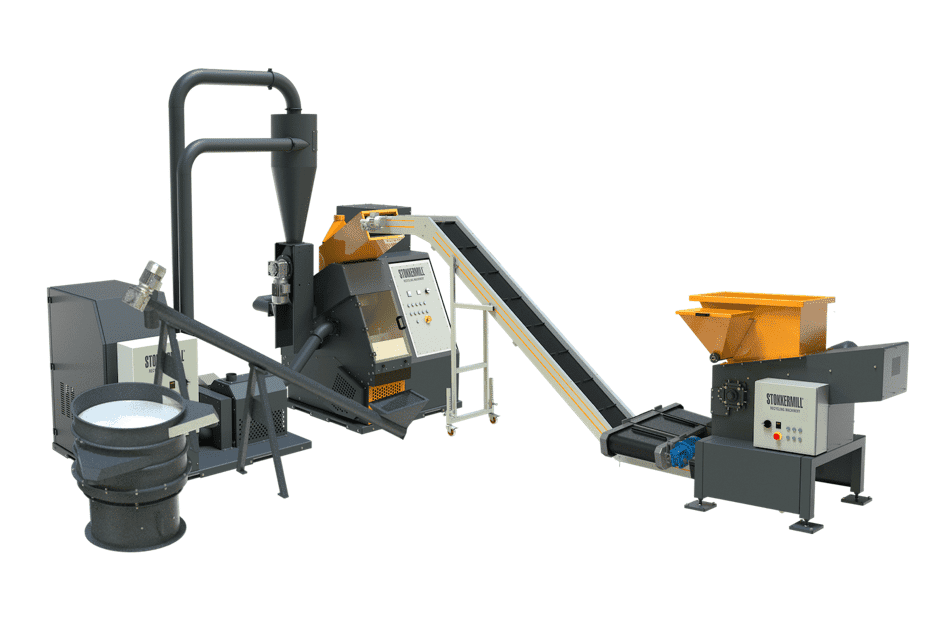

Stockkermill Copper Recycling Plant | Turboflex

Description :

Cable granulation plant, copper and aluminum grinding: Stokkermill manufactures machines and equipment that work by granulating and separating copper from the insulating part, or copper from aluminum. Recycling systems created to optimize output quality, simple, reliable and practical. The Stokkermill electric cable granulation line has a large grinding and separation capacity to meet specific needs. In the first phase of processing, the PS series pre-crusher reduces the size of the material, and the next step is to remove all metal impurities with a magnetic separator. The processing and recycling of the electric cable continues with the Turboflex crusher that allows the electric cables to be shredded and the metal part (copper or aluminum) to be separated from the plastic. The last step is then screening and classification with a vibrating screen. The main objective of cable recycling is to reuse copper to reduce the extraction of new natural resources and promote the circular economy. Correct disposal of used cables allows perfect separation of the insulating material (PVC and/or rubber) from the metal with a purity close to 100 %.

Need equipment for your demolition and recovery projects?

Contact us for more details!

Model

Version

Engine

Weight

Need equipment for your demolition and recovery projects?

Contact us for more details!

Stockkermill Copper Recycling Plant | Turboflex

Description :

Cable granulation plant, copper and aluminum grinding: Stokkermill manufactures machines and equipment that work by granulating and separating copper from the insulating part, or copper from aluminum. Recycling systems created to optimize output quality, simple, reliable and practical. The Stokkermill electric cable granulation line has a large grinding and separation capacity to meet specific needs. In the first phase of processing, the PS series pre-crusher reduces the size of the material, and the next step is to remove all metal impurities with a magnetic separator. The processing and recycling of the electric cable continues with the Turboflex crusher that allows the electric cables to be shredded and the metal part (copper or aluminum) to be separated from the plastic. The last step is then screening and classification with a vibrating screen. The main objective of cable recycling is to reuse copper to reduce the extraction of new natural resources and promote the circular economy. Correct disposal of used cables allows perfect separation of the insulating material (PVC and/or rubber) from the metal with a purity close to 100 %.

Need equipment for your demolition and recovery projects?

Contact us for more details!

Need equipment for your demolition and recovery projects?

Contact us for more details!

Stokkermill Wire Shredder | Turboflex

Description :

Cable granulator TURBOFLEX are equipped with a cell refiner downstream of the blade crusher and are available in 2 models with flow rates ranging from 170 to 350 kg/h. The presence of the turbocellular refiner allows the processing of small diameter cables (also telephone cables and data or capillary cables) without the need to modify the sorting grid or carry out costly manual work to separate the material to be processed.

Cable granulator Turboflex can be equipped with a Zig-Zag system for separating the rigid cable. Particularly robust and reliable, they enable the processing of copper and aluminium cables and copper-aluminium radiators thanks to the robust 3-blade rotating shredders. All shredders installed in the TURBOFLEX series granulators are made of a single block of steel without welded parts. The generously dimensioned motors overcome unexpected stresses, guaranteeing uniform operation and extremely low energy consumption.

Cable granulator TURBOFLEX do not require forced cooling systems due to the generous dimensioning of all process components, transport pipes and material dosing cyclones.

Cable granulator TURBOFLEX can be connected to the PS or CRS series pre-crushing machines by means of an NST series conveyor to form a complete recycling plant.

Advantages :

- Possibility to process small diameter cables without the need for costly sorting of the material to be processed (extremely fine cables, standard and large diameter cables can be processed together)

- Ease of use

- Adaptability and robustness

- Quiet operation thanks to the Silent Technology system

- Reduced maintenance time

- Low operating costs

- Do not require forced water cooling

Need equipment for your demolition and recovery projects?

Contact us for more details!

Need equipment for your demolition and recovery projects?

Contact us for more details!

Stokkermill Copper Recycling Line | K

Description: Cable granulator with external filtration system : Cable granulator are the newest entry-level shredders in our series, On the other hand, we designed the KS series keeping the same quality as other Stokkermill cable shredders. We kept the same size of densimetric separation table and blade length. Usually, a small cable granulator has a small separation table, therefore, it is very important that Stokkermill KS series small granulators have a generous size of densimetric separation table and blade length. This is very important to get the copper that deserves quality! Thanks to the high-quality components, the K-85S and K-130S show impressive performance! We use Siemens electric motors and SKF bearings and Schneider components for the control panel. Of course, we kept the same air flow adjustment dial and reverse crusher system on the control panel. Stokkermill KS series cable and wire granulator also comes with an external filtration system with a capacity of 25 m3, therefore, it is incredibly efficient to operate without stopping to clean the machine every hour.

The possibility of increasing production capacity : The production capacity of K-85S is 80-100kg/h, K-130S is 100-130kg/h depending on input material. In addition, according to customer needs, both granulators are designed and adaptable for installing a turbo unit to process even thin cables/VHU/IT and increase the production capacity. It can be added a PS series pre-crusher and a NST series conveyor belt with a magnetic pulley.

Advantages : The new entry-level compact wire granulator for copper and aluminum cables with external filtration system, High purity output materials, High quality components: Siemens motors, SKF bearings, Schneider components for the control panel, Recover copper and aluminum powder directly from the densimetric separation table, Affordable price and minimal maintenance / 24 months warranty

Need equipment for your demolition and recovery projects?

Contact us for more details!

Need equipment for your demolition and recovery projects?

Contact us for more details!

Stokkermill Wire Recycling Plant | Multiflex

Description :

Copper cable granulator of the Multi-Flex Turbo Zig-Zag series are composed of 3 units: Grinder, Refining turbine, Densimetric table.

Copper cable granulator separate significantly increases the performance and flexibility of the granulator and reduces vibration phenomena by improving the dissipation of heat produced by grinding, as well as facilitating routine maintenance.

All Multi-flex Turbo Zig-Zag systems use a TURBO cell refiner and are available in 4 models with production starting from 400 kgh.

The presence of the TURBO cell refiner allows the processing of small diameter cables (telephone and data cables or capillary cables) without the need to modify the processing grid or carry out costly operations to separate the material to be processed.

Crushers, Cable Granulator Multi-flex Turbo are equipped with a zigzag system for separating the rigid cable.

Particularly robust and reliable, they allow the processing of copper and aluminium cables and copper-aluminium radiators thanks to the robustness of the crushers.

The generously sized motors allow to overcome unexpected stresses, guaranteeing uniformity of operation and low energy consumption.

Copper Cable Granulation System Multi-flex Turbo Zig-Zag do not require forced cooling systems due to the generous dimensioning of all process components, transport lines and material dosing cyclones.

Multi-flex Turbo Zig-Zag cable granulation shredders can be connected to PS or CSR series pre-shredders by means of an NST series conveyor to form a complete recycling plant.

Advantages :

- Possibility to process small diameter cables without costly sorting of the material to be processed (extremely fine cables, standard and large diameter cables can be processed together)

- Ease of use

- Reliability and robustness

- Quiet operation thanks to the Silent Technology system

- Reduced maintenance time

- Low operating costs

- Do not require forced cooling

Need equipment for your demolition and recovery projects?

Contact us for more details!

Need equipment for your demolition and recovery projects?

Contact us for more details!

Stockkermill Copper Recycling Plant | Turboflex

Description :

Cable granulation plant, copper and aluminum grinding: Stokkermill manufactures machines and equipment that work by granulating and separating copper from the insulating part, or copper from aluminum. Recycling systems created to optimize output quality, simple, reliable and practical. The Stokkermill electric cable granulation line has a large grinding and separation capacity to meet specific needs. In the first phase of processing, the PS series pre-crusher reduces the size of the material, and the next step is to remove all metal impurities with a magnetic separator. The processing and recycling of the electric cable continues with the Turboflex crusher that allows the electric cables to be shredded and the metal part (copper or aluminum) to be separated from the plastic. The last step is then screening and classification with a vibrating screen. The main objective of cable recycling is to reuse copper to reduce the extraction of new natural resources and promote the circular economy. Correct disposal of used cables allows perfect separation of the insulating material (PVC and/or rubber) from the metal with a purity close to 100 %.