Hammel

Rockster

Stokkermill

VTN

Need equipment for your demolition and recovery projects?

Contact us for more details!

Stokkermill Turbo

Description :

Crusher, Copper Cable Separator of the Stokkermill TURBO range are all equipped with a cell refining system (TURBO) installed after the blade mill.

Crusher, Copper Cable Separator are available in 3 models with a productivity between 170 Kg/h and 400 Kg/h. The TURBO cell refining system allows the machining of thin cables (telephone cables, digital cables), working without changing the sorting grid or doing a long sorting before crushing.

Crusher, Copper Cable Separator, robust and reliable, equipped with 3 or 5 blade grinding mills, these granulators are designed for the processing of copper, aluminum cables and copper / aluminum radiators. All the mills in the TURBO range are obtained from a single block of steel, without welds.

The power of the oversized engine allowed to overcome unforeseen overloads, guaranteeing the work and always with a low energy absorption. The granulators of the TURBO range do not require cooling systems thanks to the design of all the process components, transport pipes and material dosing cyclones.

It is possible to connect all the granulators of the TURBO range to the crushers of the PS range or the CSR range via a conveyor belt of the NST range: this allows a complete recycling installation to be carried out.

Advantages :

- Possibility to process small diameter cables, without the need for sorting of the material to be processed (extremely thin cables, standard and large diameter cables can be processed together)

- Easy to use

- Reliability and robustness

- Quiet operation thanks to silent technology

- Reduced maintenance time

- Low operating costs

- Does not require water for forced cooling

- Available mobile version on tracks or semi-mobile

Need equipment for your demolition and recovery projects?

Contact us for more details!

Model

Version

Engine

Weight

Need equipment for your demolition and recovery projects?

Contact us for more details!

Stokkermill Turbo

Description :

Crusher, Copper Cable Separator of the Stokkermill TURBO range are all equipped with a cell refining system (TURBO) installed after the blade mill.

Crusher, Copper Cable Separator are available in 3 models with a productivity between 170 Kg/h and 400 Kg/h. The TURBO cell refining system allows the machining of thin cables (telephone cables, digital cables), working without changing the sorting grid or doing a long sorting before crushing.

Crusher, Copper Cable Separator, robust and reliable, equipped with 3 or 5 blade grinding mills, these granulators are designed for the processing of copper, aluminum cables and copper / aluminum radiators. All the mills in the TURBO range are obtained from a single block of steel, without welds.

The power of the oversized engine allowed to overcome unforeseen overloads, guaranteeing the work and always with a low energy absorption. The granulators of the TURBO range do not require cooling systems thanks to the design of all the process components, transport pipes and material dosing cyclones.

It is possible to connect all the granulators of the TURBO range to the crushers of the PS range or the CSR range via a conveyor belt of the NST range: this allows a complete recycling installation to be carried out.

Advantages :

- Possibility to process small diameter cables, without the need for sorting of the material to be processed (extremely thin cables, standard and large diameter cables can be processed together)

- Easy to use

- Reliability and robustness

- Quiet operation thanks to silent technology

- Reduced maintenance time

- Low operating costs

- Does not require water for forced cooling

- Available mobile version on tracks or semi-mobile

Need equipment for your demolition and recovery projects?

Contact us for more details!

Need equipment for your demolition and recovery projects?

Contact us for more details!

Stokkermill Teak Series

Description :

Separator for shredding and separating Teck cables: The TECK series separation tables are specially designed for recycling TECK cables. These cables have an inner part made of copper and an outer protection, usually made of aluminium. The TECK series cutting tables allow a high level of separation, even between metals or materials with similar specific gravity. The adjustable vibration frequency, table inclination and air flow also allow the TECK series cutting tables to be used separately. To improve the quality of raw materials in existing recycling plants, the TECK series separation tables can also be added to recycling plants and lines designed and built by Stokkermill.

• Recycling of TECK cables

• Shredding of TECK cables

TECK Cable Separators are available in different configurations according to the specific needs of the end customer and with capacities ranging from 100 to over 1500 kg/h. Larger capacity separators are available on request.

Need equipment for your demolition and recovery projects?

Contact us for more details!

Model

Version

Engine

Weight

Need equipment for your demolition and recovery projects?

Contact us for more details!

Stokkermill Teak Series

Description :

Separator for shredding and separating Teck cables: The TECK series separation tables are specially designed for recycling TECK cables. These cables have an inner part made of copper and an outer protection, usually made of aluminium. The TECK series cutting tables allow a high level of separation, even between metals or materials with similar specific gravity. The adjustable vibration frequency, table inclination and air flow also allow the TECK series cutting tables to be used separately. To improve the quality of raw materials in existing recycling plants, the TECK series separation tables can also be added to recycling plants and lines designed and built by Stokkermill.

• Recycling of TECK cables

• Shredding of TECK cables

TECK Cable Separators are available in different configurations according to the specific needs of the end customer and with capacities ranging from 100 to over 1500 kg/h. Larger capacity separators are available on request.

Need equipment for your demolition and recovery projects?

Contact us for more details!

Need equipment for your demolition and recovery projects?

Contact us for more details!

Stokkermill VT Series

Description :

Densimetric separation by shaking of the Stokkermill VT range are designed for the separation between materials with different specific weights and are equipped with systems for adjusting the vibration frequency, table inclination and air flow pressure: all this to guarantee a high standard of purity of the separated materials.

We can gift them Shaking separation densimetric tables Stokkermill with pneumatic conveying system, cyclone and star valve for dosing, suction filter for the dust produced.

Advantages :

- Electrical cables to separate the metal part from the insulation

- Recycling or machining of plastic materials

- Recycling or machining wood

- WEEE recycling

- Recycling of printed circuits

- Improvement of waste from the grinding of: ASR – car fluff – Zurik – Zorba

Need equipment for your demolition and recovery projects?

Contact us for more details!

Model

Version

Engine

Weight

Need equipment for your demolition and recovery projects?

Contact us for more details!

Stokkermill VT Series

Description :

Densimetric separation by shaking of the Stokkermill VT range are designed for the separation between materials with different specific weights and are equipped with systems for adjusting the vibration frequency, table inclination and air flow pressure: all this to guarantee a high standard of purity of the separated materials.

We can gift them Shaking separation densimetric tables Stokkermill with pneumatic conveying system, cyclone and star valve for dosing, suction filter for the dust produced.

Advantages :

- Electrical cables to separate the metal part from the insulation

- Recycling or machining of plastic materials

- Recycling or machining wood

- WEEE recycling

- Recycling of printed circuits

- Improvement of waste from the grinding of: ASR – car fluff – Zurik – Zorba

Need equipment for your demolition and recovery projects?

Contact us for more details!

Need equipment for your demolition and recovery projects?

Contact us for more details!

Stokkermill SS100

Description :

Stainless steel separator, sorter Stokkermill SS100 is a challenge for the recycling industry. The stainless steel alloy is protected by an extremely thin layer of oxides. If the layer is broken as a result of a granulation, grinding or impact process, the non-magnetic becomes a weak magnetic alloy that can be captured by the magnetic field of the cylinder allowing separation within certain limits and respecting certain conditions. The smaller the fragments of weak magnetic metal, the lower the magnetic attraction capacity. This means that the best results can be achieved with particles >= 1 mm. The highest efficiency of the magnetic field that can be achieved within 10 mm of the magnetic cylinder is extremely important to properly distribute the materials in a thin layer on the magnetic cylinder.

Separation of stainless steel particles SS100 is equipped with a vibration loading table to spread the material on the cylinder allowing the best possible separation. The Stokkermill SS100 stainless steel separator is able to separate stainless steel particles from pre-processed materials in the recycling and recovery of electrical and electronic materials (WEEE), car lint (ASR), Zurik and Zorba and generally from shredded residues. The SS100 stainless steel separator is also used in the field of plastic recycling and regeneration, where it is important to separate metallic and ferrous impurities in order to protect the extrusion and molding processes. The SS100 is available in different sizes and magnetic field strengths and can be configured in cascade where high output purity standards are required.

Need equipment for your demolition and recovery projects?

Contact us for more details!

Model

Version

Engine

Weight

Need equipment for your demolition and recovery projects?

Contact us for more details!

Stokkermill SS100

Description :

Stainless steel separator, sorter Stokkermill SS100 is a challenge for the recycling industry. The stainless steel alloy is protected by an extremely thin layer of oxides. If the layer is broken as a result of a granulation, grinding or impact process, the non-magnetic becomes a weak magnetic alloy that can be captured by the magnetic field of the cylinder allowing separation within certain limits and respecting certain conditions. The smaller the fragments of weak magnetic metal, the lower the magnetic attraction capacity. This means that the best results can be achieved with particles >= 1 mm. The highest efficiency of the magnetic field that can be achieved within 10 mm of the magnetic cylinder is extremely important to properly distribute the materials in a thin layer on the magnetic cylinder.

Separation of stainless steel particles SS100 is equipped with a vibration loading table to spread the material on the cylinder allowing the best possible separation. The Stokkermill SS100 stainless steel separator is able to separate stainless steel particles from pre-processed materials in the recycling and recovery of electrical and electronic materials (WEEE), car lint (ASR), Zurik and Zorba and generally from shredded residues. The SS100 stainless steel separator is also used in the field of plastic recycling and regeneration, where it is important to separate metallic and ferrous impurities in order to protect the extrusion and molding processes. The SS100 is available in different sizes and magnetic field strengths and can be configured in cascade where high output purity standards are required.

Need equipment for your demolition and recovery projects?

Contact us for more details!

Need equipment for your demolition and recovery projects?

Contact us for more details!

Stokkermill E Sorting Separation

Description :

Electrostatic Separators of the E-Sorting range are the latest frontier of technology in the separation of unclassified materials. Thanks to electric fields, it is possible to separate the conductive part (metallic) from the insulating part (paper, cardboard, plastic, rubber), the paper from the plastic, the organic part from the inert part: all with a very fine particle size.

Electrostatic Separators are simple to use, economical and with low management costs.

The technology uses differential conductivity between different materials. Insulators (less conductive) remain on the roller connected to ground by an electrostatic force, while conductors, which lose their charge, are thrown off the roller.

Electrostatic Separators E-Sorting can be used individually or in series, depending on the input materials. There are two standard sizes in the range with 600 or 1200 mm shafts.

Areas of use:

- Recovery of light fractions of precious metals (gold, silver, palladium) in the recycling processes of electrical and electronic printed circuits, WEEE

- Recovery of light fractions of metals (copper and aluminum) which are in the plastic fraction from electrical cable recycling operations

- Separation of plastics with different dielectric properties (e.g. shredded window frames separating aluminum from plastic)

- Recycling girls

- Separate the plastics (insulators) from the conductors (copper and aluminum)

- Separate conductors (copper and aluminum);

- Recycling of secondary metals;

- Mineral processing (eg. Used in conjunction with high intensity magnetic separators to separate beach sands)

Need equipment for your demolition and recovery projects?

Contact us for more details!

Model

Version

Engine

Weight

Need equipment for your demolition and recovery projects?

Contact us for more details!

Stokkermill E Sorting Separation

Description :

Electrostatic Separators of the E-Sorting range are the latest frontier of technology in the separation of unclassified materials. Thanks to electric fields, it is possible to separate the conductive part (metallic) from the insulating part (paper, cardboard, plastic, rubber), the paper from the plastic, the organic part from the inert part: all with a very fine particle size.

Electrostatic Separators are simple to use, economical and with low management costs.

The technology uses differential conductivity between different materials. Insulators (less conductive) remain on the roller connected to ground by an electrostatic force, while conductors, which lose their charge, are thrown off the roller.

Electrostatic Separators E-Sorting can be used individually or in series, depending on the input materials. There are two standard sizes in the range with 600 or 1200 mm shafts.

Areas of use:

- Recovery of light fractions of precious metals (gold, silver, palladium) in the recycling processes of electrical and electronic printed circuits, WEEE

- Recovery of light fractions of metals (copper and aluminum) which are in the plastic fraction from electrical cable recycling operations

- Separation of plastics with different dielectric properties (e.g. shredded window frames separating aluminum from plastic)

- Recycling girls

- Separate the plastics (insulators) from the conductors (copper and aluminum)

- Separate conductors (copper and aluminum);

- Recycling of secondary metals;

- Mineral processing (eg. Used in conjunction with high intensity magnetic separators to separate beach sands)

Need equipment for your demolition and recovery projects?

Contact us for more details!

Need equipment for your demolition and recovery projects?

Contact us for more details!

Stokkermill Zig Zag Aeraulic Separator

Description :

Stokkermill ZZ range air separators are designed to remove the light part of unclassified waste using a counter-current air flow in a zigzag duct.

Zigzag separators are normally installed after grinding to improve product quality.

They are ideal for cleaning residues from grinding (ASR, car fluff, Zurik, Zorba), for separating the heavy part of copper and aluminium after grinding cables, for separating, in general, all light parts from heavy parts.

Made to order.

Air Zig Zag Separators can be easily installed on the Stokkermill Multiflex Turbo Zig-Zag cable copper granulator which allow the separation of the rigid fraction from the diluent or capillary fraction.

Need equipment for your demolition and recovery projects?

Contact us for more details!

Model

Version

Engine

Weight

Need equipment for your demolition and recovery projects?

Contact us for more details!

Stokkermill Zig Zag Aeraulic Separator

Description :

Stokkermill ZZ range air separators are designed to remove the light part of unclassified waste using a counter-current air flow in a zigzag duct.

Zigzag separators are normally installed after grinding to improve product quality.

They are ideal for cleaning residues from grinding (ASR, car fluff, Zurik, Zorba), for separating the heavy part of copper and aluminium after grinding cables, for separating, in general, all light parts from heavy parts.

Made to order.

Air Zig Zag Separators can be easily installed on the Stokkermill Multiflex Turbo Zig-Zag cable copper granulator which allow the separation of the rigid fraction from the diluent or capillary fraction.

Need equipment for your demolition and recovery projects?

Contact us for more details!

Need equipment for your demolition and recovery projects?

Contact us for more details!

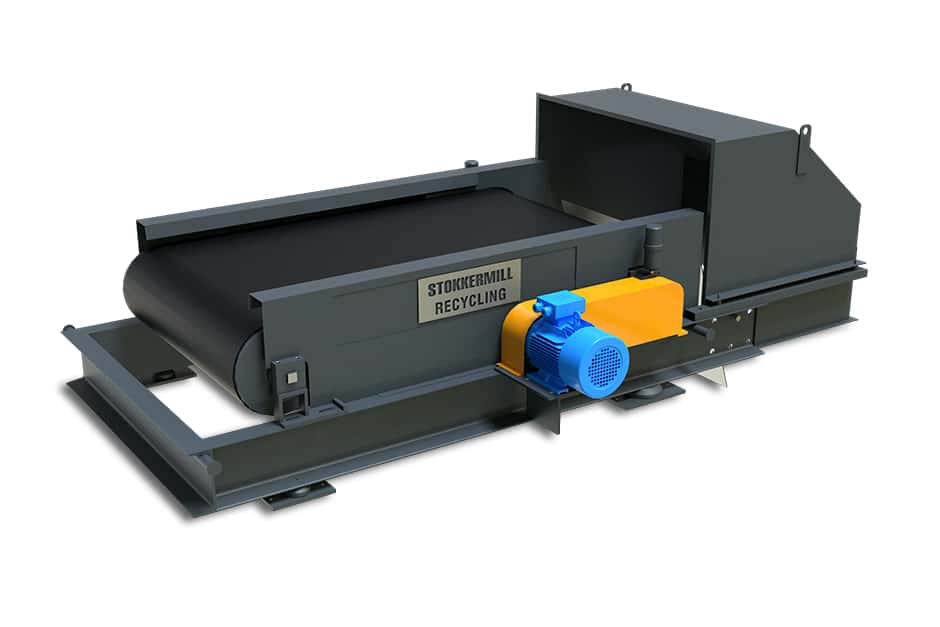

Stokkermill Metal Recovery

Description :

Eddy current non-ferrous waste separators are a system for the recovery of non-ferrous metals in a waste recovery line that produces materials between 1 and 300 mm.

The areas of application of eddy current separators are very wide in separating very small parts of non-ferrous metals.

On a conveyor belt, a magnetic rotor is placed which turns very quickly and creates an induced electric current which moves the parts of non-ferrous metals with low conductivity in the flow of materials.

Advantages :

- Low operating costs

- Easy maintenance

- Reliability and precision of operation

Need equipment for your demolition and recovery projects?

Contact us for more details!

Model

Version

Engine

Weight

Need equipment for your demolition and recovery projects?

Contact us for more details!

Stokkermill Metal Recovery

Description :

Eddy current non-ferrous waste separators are a system for the recovery of non-ferrous metals in a waste recovery line that produces materials between 1 and 300 mm.

The areas of application of eddy current separators are very wide in separating very small parts of non-ferrous metals.

On a conveyor belt, a magnetic rotor is placed which turns very quickly and creates an induced electric current which moves the parts of non-ferrous metals with low conductivity in the flow of materials.

Advantages :

- Low operating costs

- Easy maintenance

- Reliability and precision of operation

Need equipment for your demolition and recovery projects?

Contact us for more details!

Need equipment for your demolition and recovery projects?

Contact us for more details!

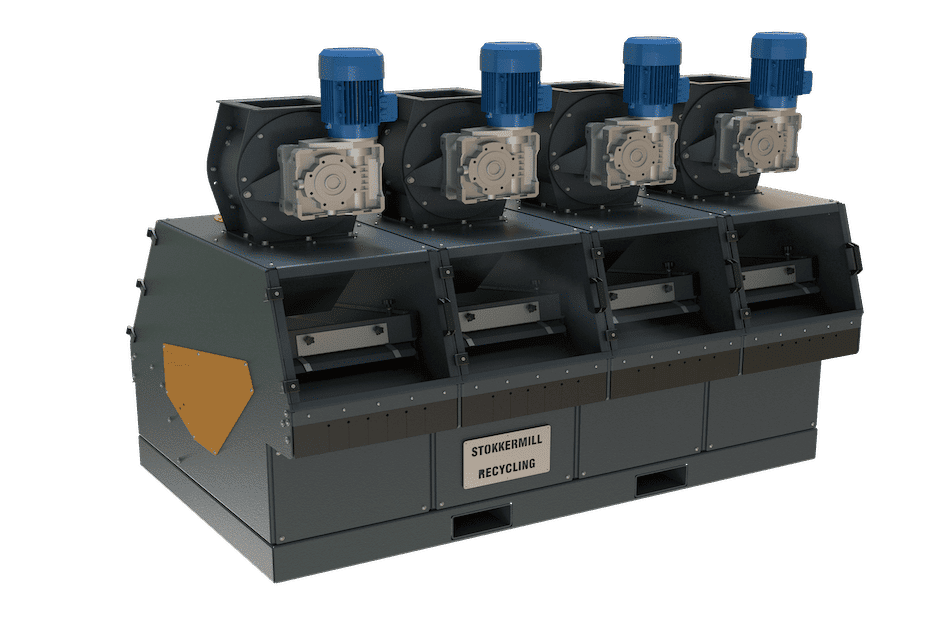

Stokkermill Metal Densimetric Separator

Description :

Multiple mixed metal separation tables are the natural evolution of dual outlet densitometric tables. The system consists of a minimum of 4 outlets up to a maximum of 8 outlets. Multiple tables allow to separate very complex materials such as WEEE electronic waste and WEEE recycling from the demolition of end-of-life vehicles. Multiple densitometric tables usually operate downstream of fine material granulation systems such as blade crushers with flow rates below 5 mm, delamination turbines or similar systems. Densitometric tables can be loaded with mechanical transport systems (conveyor belts, screw conveyors, pneumatic transport systems). Multiple separation tables can be manufactured in different sizes according to the operational needs of the end user. Multiple outlet dry separation systems are controlled by an inverter that allows you to adjust the vibration speed to improve the quality of the output materials; Likewise, the table tilt can be easily adjusted within a range of about 10°.

Advantages :

- Separation of electrical and electronic equipment WEEE

- Separation of electrical cables

- Separation of electronic cards

- Separation of electronic equipment from vehicle dismantling

- Separation of different metals

- Separation of aluminum and copper

- Separation of copper and plastic

- Separation of aluminum and plastic

- Separation of copper-aluminum-plastic automotive radiators

- Separation of copper-aluminum-plastic industrial radiators

Need equipment for your demolition and recovery projects?

Contact us for more details!

Model

Version

Engine

Weight

Need equipment for your demolition and recovery projects?

Contact us for more details!

Stokkermill Metal Densimetric Separator

Description :

Multiple mixed metal separation tables are the natural evolution of dual outlet densitometric tables. The system consists of a minimum of 4 outlets up to a maximum of 8 outlets. Multiple tables allow to separate very complex materials such as WEEE electronic waste and WEEE recycling from the demolition of end-of-life vehicles. Multiple densitometric tables usually operate downstream of fine material granulation systems such as blade crushers with flow rates below 5 mm, delamination turbines or similar systems. Densitometric tables can be loaded with mechanical transport systems (conveyor belts, screw conveyors, pneumatic transport systems). Multiple separation tables can be manufactured in different sizes according to the operational needs of the end user. Multiple outlet dry separation systems are controlled by an inverter that allows you to adjust the vibration speed to improve the quality of the output materials; Likewise, the table tilt can be easily adjusted within a range of about 10°.

Advantages :

- Separation of electrical and electronic equipment WEEE

- Separation of electrical cables

- Separation of electronic cards

- Separation of electronic equipment from vehicle dismantling

- Separation of different metals

- Separation of aluminum and copper

- Separation of copper and plastic

- Separation of aluminum and plastic

- Separation of copper-aluminum-plastic automotive radiators

- Separation of copper-aluminum-plastic industrial radiators

Need equipment for your demolition and recovery projects?

Contact us for more details!

Need equipment for your demolition and recovery projects?

Contact us for more details!

Stokkermill Turbo

Description :

Crusher, Copper Cable Separator of the Stokkermill TURBO range are all equipped with a cell refining system (TURBO) installed after the blade mill.

Crusher, Copper Cable Separator are available in 3 models with a productivity between 170 Kg/h and 400 Kg/h. The TURBO cell refining system allows the machining of thin cables (telephone cables, digital cables), working without changing the sorting grid or doing a long sorting before crushing.

Crusher, Copper Cable Separator, robust and reliable, equipped with 3 or 5 blade grinding mills, these granulators are designed for the processing of copper, aluminum cables and copper / aluminum radiators. All the mills in the TURBO range are obtained from a single block of steel, without welds.

The power of the oversized engine allowed to overcome unforeseen overloads, guaranteeing the work and always with a low energy absorption. The granulators of the TURBO range do not require cooling systems thanks to the design of all the process components, transport pipes and material dosing cyclones.

It is possible to connect all the granulators of the TURBO range to the crushers of the PS range or the CSR range via a conveyor belt of the NST range: this allows a complete recycling installation to be carried out.

Advantages :

- Possibility to process small diameter cables, without the need for sorting of the material to be processed (extremely thin cables, standard and large diameter cables can be processed together)

- Easy to use

- Reliability and robustness

- Quiet operation thanks to silent technology

- Reduced maintenance time

- Low operating costs

- Does not require water for forced cooling

- Available mobile version on tracks or semi-mobile

Need equipment for your demolition and recovery projects?

Contact us for more details!

Need equipment for your demolition and recovery projects?

Contact us for more details!

Stokkermill Teak Series

Description :

Separator for shredding and separating Teck cables: The TECK series separation tables are specially designed for recycling TECK cables. These cables have an inner part made of copper and an outer protection, usually made of aluminium. The TECK series cutting tables allow a high level of separation, even between metals or materials with similar specific gravity. The adjustable vibration frequency, table inclination and air flow also allow the TECK series cutting tables to be used separately. To improve the quality of raw materials in existing recycling plants, the TECK series separation tables can also be added to recycling plants and lines designed and built by Stokkermill.

• Recycling of TECK cables

• Shredding of TECK cables

TECK Cable Separators are available in different configurations according to the specific needs of the end customer and with capacities ranging from 100 to over 1500 kg/h. Larger capacity separators are available on request.

Need equipment for your demolition and recovery projects?

Contact us for more details!

Need equipment for your demolition and recovery projects?

Contact us for more details!

Stokkermill VT Series

Description :

Densimetric separation by shaking of the Stokkermill VT range are designed for the separation between materials with different specific weights and are equipped with systems for adjusting the vibration frequency, table inclination and air flow pressure: all this to guarantee a high standard of purity of the separated materials.

We can gift them Shaking separation densimetric tables Stokkermill with pneumatic conveying system, cyclone and star valve for dosing, suction filter for the dust produced.

Advantages :

- Electrical cables to separate the metal part from the insulation

- Recycling or machining of plastic materials

- Recycling or machining wood

- WEEE recycling

- Recycling of printed circuits

- Improvement of waste from the grinding of: ASR – car fluff – Zurik – Zorba

Need equipment for your demolition and recovery projects?

Contact us for more details!

Need equipment for your demolition and recovery projects?

Contact us for more details!

Stokkermill SS100

Description :

Stainless steel separator, sorter Stokkermill SS100 is a challenge for the recycling industry. The stainless steel alloy is protected by an extremely thin layer of oxides. If the layer is broken as a result of a granulation, grinding or impact process, the non-magnetic becomes a weak magnetic alloy that can be captured by the magnetic field of the cylinder allowing separation within certain limits and respecting certain conditions. The smaller the fragments of weak magnetic metal, the lower the magnetic attraction capacity. This means that the best results can be achieved with particles >= 1 mm. The highest efficiency of the magnetic field that can be achieved within 10 mm of the magnetic cylinder is extremely important to properly distribute the materials in a thin layer on the magnetic cylinder.

Separation of stainless steel particles SS100 is equipped with a vibration loading table to spread the material on the cylinder allowing the best possible separation. The Stokkermill SS100 stainless steel separator is able to separate stainless steel particles from pre-processed materials in the recycling and recovery of electrical and electronic materials (WEEE), car lint (ASR), Zurik and Zorba and generally from shredded residues. The SS100 stainless steel separator is also used in the field of plastic recycling and regeneration, where it is important to separate metallic and ferrous impurities in order to protect the extrusion and molding processes. The SS100 is available in different sizes and magnetic field strengths and can be configured in cascade where high output purity standards are required.

Need equipment for your demolition and recovery projects?

Contact us for more details!

Need equipment for your demolition and recovery projects?

Contact us for more details!

Stokkermill E Sorting Separation

Description :

Electrostatic Separators of the E-Sorting range are the latest frontier of technology in the separation of unclassified materials. Thanks to electric fields, it is possible to separate the conductive part (metallic) from the insulating part (paper, cardboard, plastic, rubber), the paper from the plastic, the organic part from the inert part: all with a very fine particle size.

Electrostatic Separators are simple to use, economical and with low management costs.

The technology uses differential conductivity between different materials. Insulators (less conductive) remain on the roller connected to ground by an electrostatic force, while conductors, which lose their charge, are thrown off the roller.

Electrostatic Separators E-Sorting can be used individually or in series, depending on the input materials. There are two standard sizes in the range with 600 or 1200 mm shafts.

Areas of use:

- Recovery of light fractions of precious metals (gold, silver, palladium) in the recycling processes of electrical and electronic printed circuits, WEEE

- Recovery of light fractions of metals (copper and aluminum) which are in the plastic fraction from electrical cable recycling operations

- Separation of plastics with different dielectric properties (e.g. shredded window frames separating aluminum from plastic)

- Recycling girls

- Separate the plastics (insulators) from the conductors (copper and aluminum)

- Separate conductors (copper and aluminum);

- Recycling of secondary metals;

- Mineral processing (eg. Used in conjunction with high intensity magnetic separators to separate beach sands)

Need equipment for your demolition and recovery projects?

Contact us for more details!

Need equipment for your demolition and recovery projects?

Contact us for more details!

Stokkermill Zig Zag Aeraulic Separator

Description :

Stokkermill ZZ range air separators are designed to remove the light part of unclassified waste using a counter-current air flow in a zigzag duct.

Zigzag separators are normally installed after grinding to improve product quality.

They are ideal for cleaning residues from grinding (ASR, car fluff, Zurik, Zorba), for separating the heavy part of copper and aluminium after grinding cables, for separating, in general, all light parts from heavy parts.

Made to order.

Air Zig Zag Separators can be easily installed on the Stokkermill Multiflex Turbo Zig-Zag cable copper granulator which allow the separation of the rigid fraction from the diluent or capillary fraction.

Need equipment for your demolition and recovery projects?

Contact us for more details!

Need equipment for your demolition and recovery projects?

Contact us for more details!

Stokkermill Metal Recovery

Description :

Eddy current non-ferrous waste separators are a system for the recovery of non-ferrous metals in a waste recovery line that produces materials between 1 and 300 mm.

The areas of application of eddy current separators are very wide in separating very small parts of non-ferrous metals.

On a conveyor belt, a magnetic rotor is placed which turns very quickly and creates an induced electric current which moves the parts of non-ferrous metals with low conductivity in the flow of materials.

Advantages :

- Low operating costs

- Easy maintenance

- Reliability and precision of operation

Need equipment for your demolition and recovery projects?

Contact us for more details!

Need equipment for your demolition and recovery projects?

Contact us for more details!

Stokkermill Metal Densimetric Separator

Description :

Multiple mixed metal separation tables are the natural evolution of dual outlet densitometric tables. The system consists of a minimum of 4 outlets up to a maximum of 8 outlets. Multiple tables allow to separate very complex materials such as WEEE electronic waste and WEEE recycling from the demolition of end-of-life vehicles. Multiple densitometric tables usually operate downstream of fine material granulation systems such as blade crushers with flow rates below 5 mm, delamination turbines or similar systems. Densitometric tables can be loaded with mechanical transport systems (conveyor belts, screw conveyors, pneumatic transport systems). Multiple separation tables can be manufactured in different sizes according to the operational needs of the end user. Multiple outlet dry separation systems are controlled by an inverter that allows you to adjust the vibration speed to improve the quality of the output materials; Likewise, the table tilt can be easily adjusted within a range of about 10°.

Advantages :

- Separation of electrical and electronic equipment WEEE

- Separation of electrical cables

- Separation of electronic cards

- Separation of electronic equipment from vehicle dismantling

- Separation of different metals

- Separation of aluminum and copper

- Separation of copper and plastic

- Separation of aluminum and plastic

- Separation of copper-aluminum-plastic automotive radiators

- Separation of copper-aluminum-plastic industrial radiators